Renault will be able to cut battery production costs by around 20% by using lithium-iron-phosphate (LFP) technology alongside the nickel-cobalt-manganese batteries it currently uses for its electric vehicles.

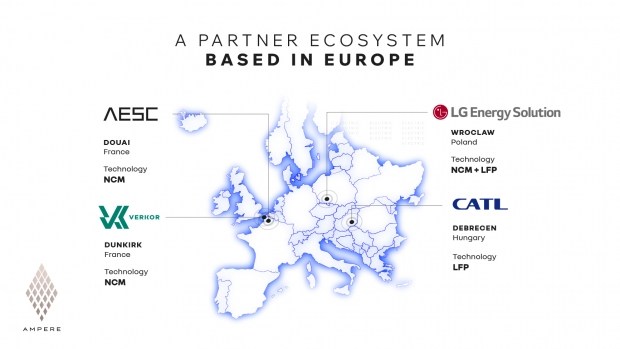

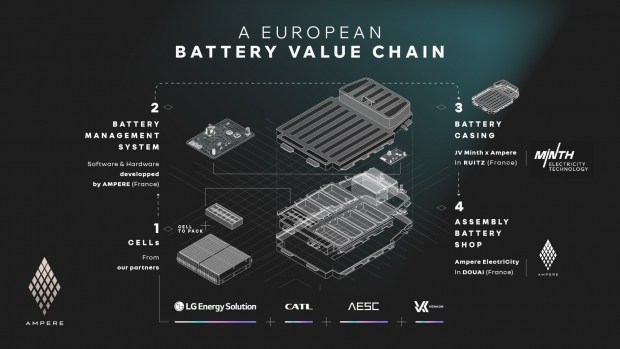

The battery division of the French manufacturer Ampere will work together with LG Energy Solution and CATL on the production of LFP batteries. Several Renault and Alpine models will use the new, cheaper batteries, which will cover all of Renault's battery needs until 2030. CATL's LFP batteries will be supplied from a plant in Hungary, while LG Energy Solution will produce its LFP batteries at a plant in Poland.

LG will also collaborate with Ampere on a new cell-to-pack technology that will allow more cells to be integrated into a battery pack, further reducing manufacturing costs.

The French company says that LFP batteries are well suited for compact cars, and besides that they are cheaper, although less energy intensive. The first Renault models with the new LFP batteries will be ready for launch in 2026.

“In a rapidly changing and competitive environment, our battery strategy is a testament to the effectiveness of Ampere's open and horizontal approach to best-in-class partners, enabling smart capital allocation, flexibility and rapid implementation”– noted Ampere Chief Operating Officer Josep Maria Recasens.

The new plan, he said, is in line with Ampere's roadmap to cut costs by 40% before production of the next generation of vehicles begins.